Remanufacture of Amada Arcade 210, 1994

Before Remanufacture

Before Remanufacture

Although cosmetically reasonable, the machine had done in excess of 20,000 hours and technically needed attention.

Replacement of auto-index punch sleeves

Replacement of auto-index punch sleeves

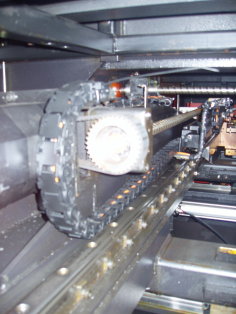

Auto index stations are used most frequently and therefore suffer the most wear. In almost all cases these require replacement as shown in the photo. New auto index drive shaft universal joints

New auto index drive shaft universal joints

In order that the auto index punches to specification and therefore exhibits no backlash on ‘stepping’ keys, belts and universal joints are replaced in the drive system.

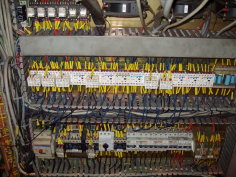

New control relays

New control relays

All control relays have a finite live and are commonly only replaced on complete failure. JTES fit new control relays (Siemens and Omron miniature) to ensure faultless operation. New high pressure hydraulic hoses

New high pressure hydraulic hoses

The Arcade 210 has 300 bar operating pressure, so old hoses frequently leak and therefore require changing. New up-rated oiltech oil cooler

New up-rated oiltech oil cooler

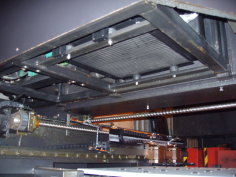

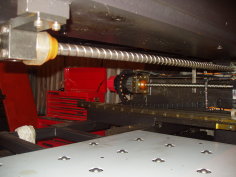

On original Arcades, oil cooling was an issue in certain circumstances. JTES machines are often fitted with NEW oiltech cooler assemblies to overcome this problem – even in tropical temperatures. New X axis wiring loom / Remanufactured X axis ballscrew

New X axis wiring loom / Remanufactured X axis ballscrew

Replaced due to general wear and tear. New (modified) Y axis wiring loom

New (modified) Y axis wiring loom

Original Y wiring loom is much smaller on pre 1996 machines, resulting in multiple cable fractures and therefore breakdowns. Where necessary JTES use larger cable management systems to eliminate known problems. Control panel membranes

Control panel membranes

New control panel membranes New upper turret door slides and interlock switches

New upper turret door slides and interlock switches

Damage to upper turret door slides – frequently due to misuse, means that door safety interlocks are frequently disabled to keep the machine running. JTES fit new parts, and reinstall all safety systems. New clamp base assemblies and clamp wiring loom/pipework

New clamp base assemblies and clamp wiring loom/pipework

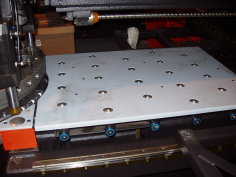

The X axis position scale, clamp sensors, associated wiring and pipework is always severely damaged by sheet wrap ups. This is resolved and reinstated to the specification of late 1998 machines. Remanufactured work tables

Remanufactured work tables

Remanufacture of Y ballscrews

Remanufacture of Y ballscrews

Y ballscrews are remanufactured to return machine accuracy to specification. Always accompanied by new belts and thrust bearings.Remanufactured Amada Arcade 210, 1994

In addition, this particular machine also benefitted from the following preventative maintenance actions;Remanufacture of main hydraulic ram cylinder, including re chrome, polish and seal

New LVDT, a part of the ram control circuit which feeds back ram position to the controller

New YV4 ram servo control valve (Bosch or Schneider)

The result....

Now you can see why JTES Ltd have the confidence to supply all their machines with a 6 months parts and labour warranty!

Insert product image into editable area below to display on Machine Remanufacture homepage: