CoastoneUK Electric Press Brakes Collaboration

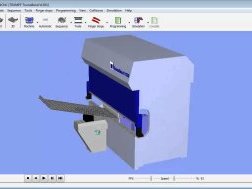

With more and more customers looking to work with offline programming, the CoastOne range of electric pressbrakes, operating with the Radan Radbend software, offers the perfect solution.

Customer can see for themselves the advantage of the system on our CoastOne G30 3m electric pressbrake demonstration machine at our Cheshire site.

Radbend from RADAN is the comprehensive offline programming solution for press brakes.

Completely integrated with RADAN3D it also provides a full 3D simulation of thebending process.

Features at a glance:

- Automatic bend sequencing

- Automated tool selection

- Tool setup optimization

- Automatic finger stop positioning

- Customisable reports

- Support for lifting aids and angle measurement systems

- Can be integrated with RADAN3D

Offline programming

Radbendenables full accurate 3D-model simulation of the bending process, includingadvanced features such as automatic bend sequence calculation, automatic toolselection and automatic finger stop placement, offering simple programming andhigh productivity.

Highly automated

Radbendfeatures high levels of automation. The system examines the part to be programmedand automatically determines a bending sequence taking into account partgeometry and best machinery practice.

Data import

Radbend canimport data in a range of 2D and 3D formats as well as having specific plug-ininterfaces for well known 3D CAD systems.

Increase productivity

- Once your part has been transferred into Radbend you will be able to:

- Select the most appropriate machine tool and the appropriate tools to bend the part correctly

- Provide you with consequences of your tool set up - expected radius, press depth etc.

- Automatically position finger stops against every valid face requiring fingerstops.

- Run a full 3D simulation of the bending process detecting any collisions and potential problems.

- Automatically generate complete shopfloor documentation, including setup sheets.

Benefits include:

- Reduce downtime through fast and reliable offline programming

- Reduce lead times due to improved efficiency

- Reduce the set up times of machine tool from the availability of manufacturing information

- Fewer design errors, due to the 3D simulation contained within Radbend

- Reducing costly manufacturing errors by making use of the collision checking

- Machine Independent means that you can easily use Radbend on any of your pressbrake machine tools

- Open up the press brake to a wider audience of employees

- Accurate automatic unfolding, even with imported models

- Increased production flexibility

Radbend can help you to reducebottlenecks and costs, whilst increasing efficiency and productivity byenabling you to program and verify your bending operations offline as well asdetecting any collisions with the tooling, finger stops and the machine toolitself.

Contact us for more details 01260297700 or enquiries@coastone.co.uk or to arrange a demo.

Insert product image into editable area below to display on homepage: